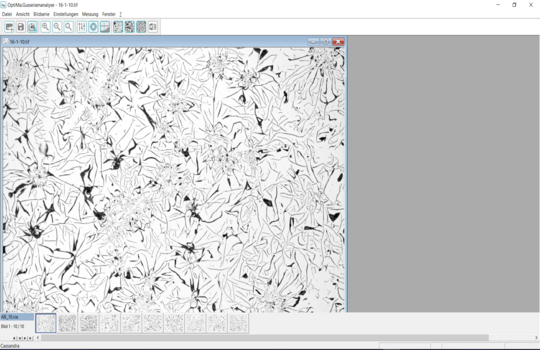

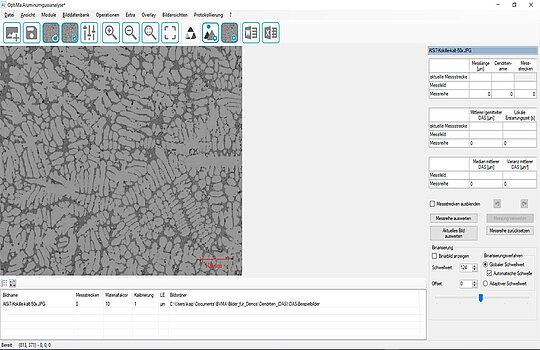

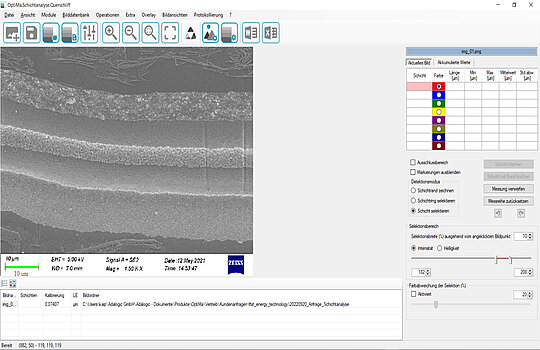

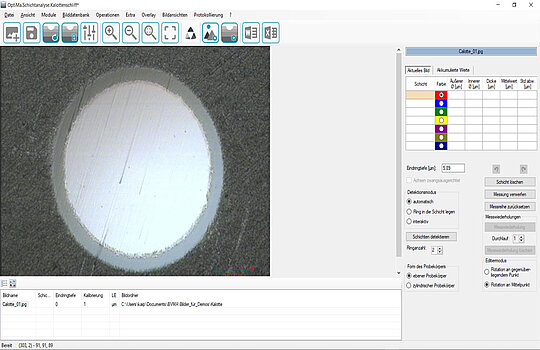

As users of the software modules for the microstructure analysis of cast iron and for layer analysis, we are very satisfied with the performance and utility of these products.

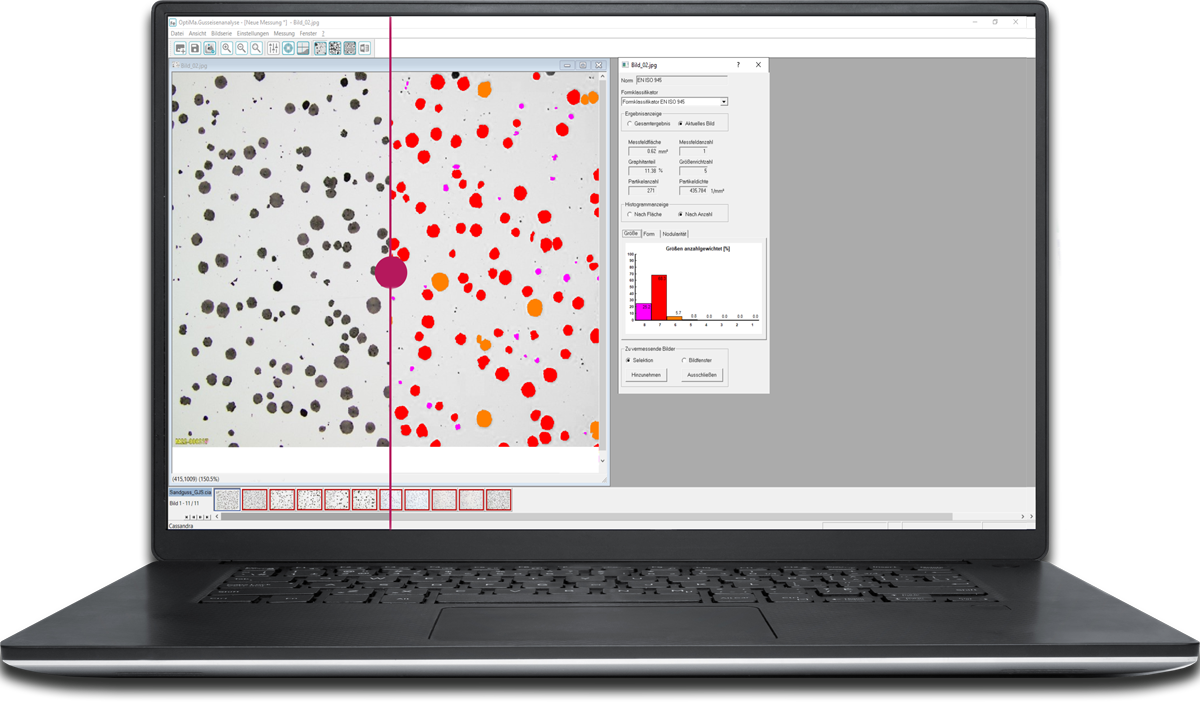

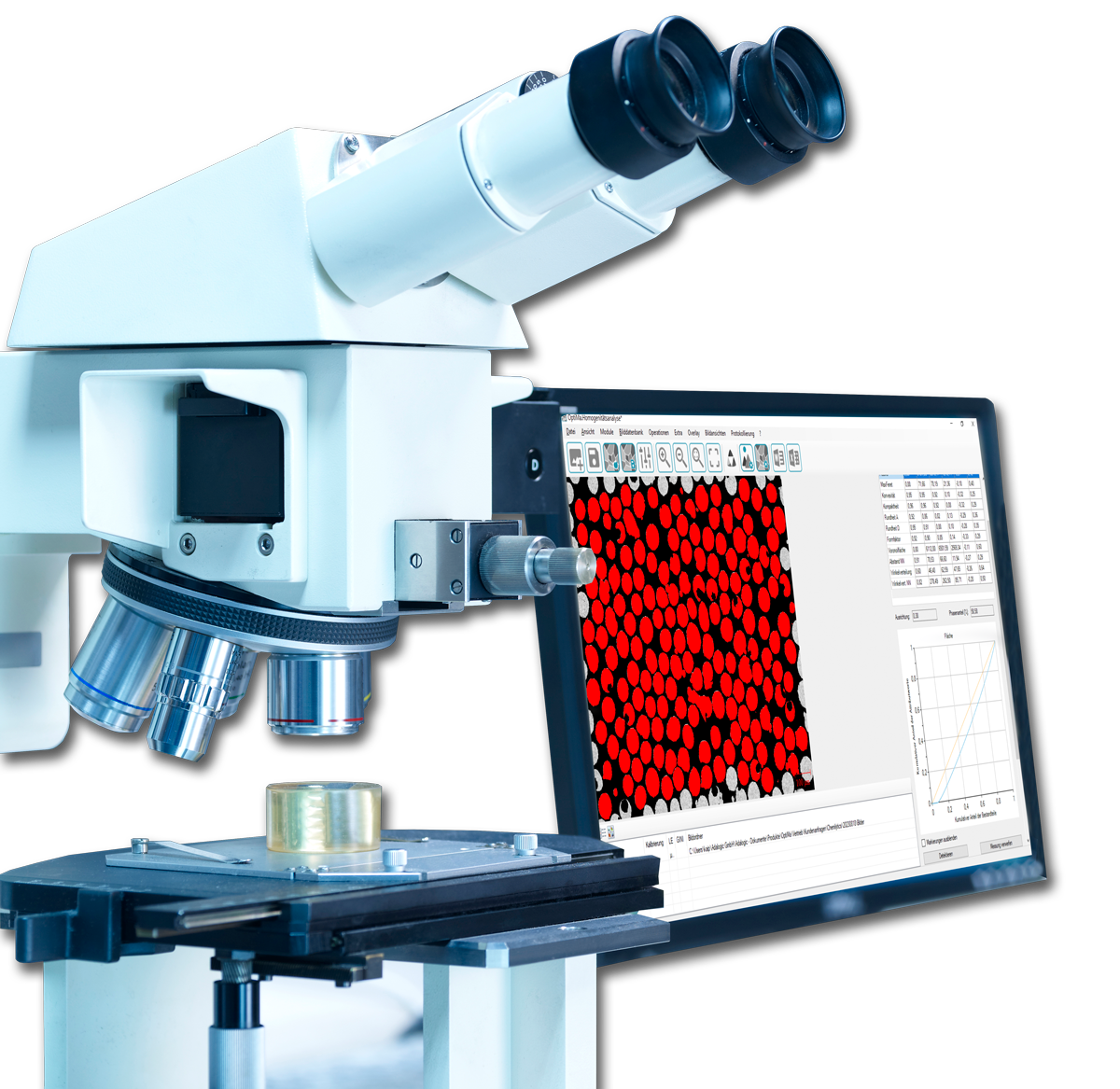

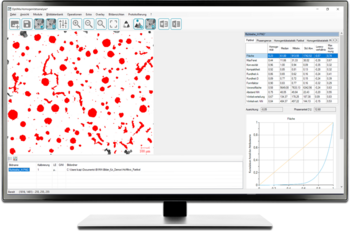

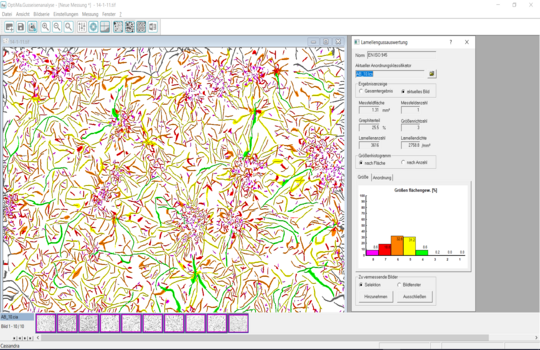

OptiMa.CastIronAnalysis provides a quick and accurate assessment of the microstructure of castings in accordance with applicable standards. OptiMa.LayerAnalysis helps us to determine the thickness and geometric properties of e.g. corrosion layers. Both modules are easy to use and provide reliable results that are very useful in materials testing and research.

Dr. Dirk Bettge, Head of Materialography, Fractography, and Aging of Technical Materials | BAM

We are very satisfied with OptiMa.CastIronAnalysis, which we have been using for several years in our company for quality assurance. We have an innovative software solution that allows us to optimize our cast iron production and ensure compliance with quality standards. The standardized evaluation of our castings can be carried out in the shortest possible time and with the highest accuracy, saving time and money and increasing our competitiveness. OptiMa.CastIronAnalysis is a worthwhile investment and I am glad that we decided to implement it.

Gerald Rohrweger, Head of Quality | Gienanth Steyr Guss GmbH

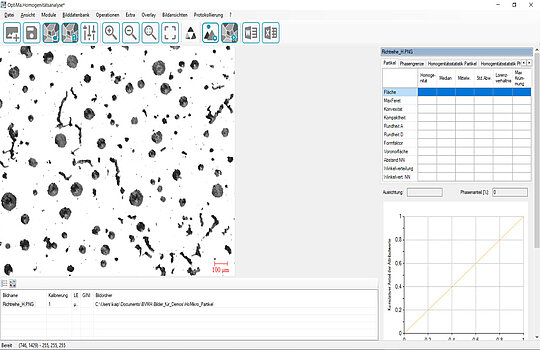

We have been using OptiMa.LayerAnalysis for 7 years and OptiMa.HomogeneityAnalysis for 18 months and we are very satisfied with the software. The modules have become vital parts of our microscopic analysis process, having extended the capabilities of our instruments greatly and allowed us to obtain statistically relevant populations of measurements with minimal user time. Furthermore, we appreciate the excellent support provided by Adalogic. We highly recommend the software to other users in the field.

Alec Goode, Materials Science Specialist | Sun Chemical